Körber Offers Preroll Solutions to Help Cannabis Brands Increase Profit

Hurtures have undeniably develop into one of many quickest rising classes within the hashish business. Customers are looking for comfort, and the period of worrying about low-quality hashish in pre-rolls has disappeared into the previous.

As well as, the introduction of cylindrical or cigarette type pre-rolls (simply pre-rolls) has raised a superb smoking expertise, including the lured of this class.

With growing gross sales figures in lots of states, the necessity to optimize manufacturing turns into most vital, particularly within the gentle of restricted monetary liquidity and accessibility of the workforce. The main focus is shifting in direction of profitability, price discount, elevated product high quality and improved attraction.

Let’s notice it; Reaching these objectives requires departure from tapered pre-rolls and slowly automated manufacturing. It is time to get inspiration from the tobacco and cigarette business’s rod manufacturing strategies.

Effectivity and precision in hashish manufacturing

Within the Nineteen Fifties, cigarettes got here in numerous types, largely lacking filters. Manufacturers like Marlboro acknowledged the potential of filters and appealed to a wider client base. Standardization of the cylindrical kind launched automation, which considerably reduces manufacturing prices. At the moment, the early adopters the worldwide cigarette market, and Körber (previously Hauni), the pioneer in filter cigareters, stands because the undisputed quantity a machine vendor for this business.

The query arises: Can this method thrive on the very fragmented US hashish market, challenged by intergovernmental shipments? The reply is affirmative, albeit in a smaller scale. Körber’s Cantos Cylindrical Pre-Roll successfully produces 40,000 pre-rolls per 12 months. 8-hour shifts. Utilization of the cigarette kind is built-in with common cigarette packages. As nationwide legalization approaches, very automated and efficient manufacturing node emerges, making it much more attractive for some to modify to the world’s quickest pre-roll maker, the Nano-HOver 1,000 pre-rolls are produced per 12 months. Minute.

Steady movement manufacturing

Cigarettes are produced in a steady movement slightly than individually rolled. This precept permits manufacturing charges of as much as 20,000 cigarettes per 12 months. Minute, whereas the best attainable high quality. Körber’s pre-roll producers embrace this steady manufacturing precept with changes to dealing with sticky hashish. Attaining manufacturing prices per Pre-roll (together with all non-cannabis supplies) under $ 0.02 turns into attainable.

© Körber Applied sciences

Filter socket: Customizing and developments

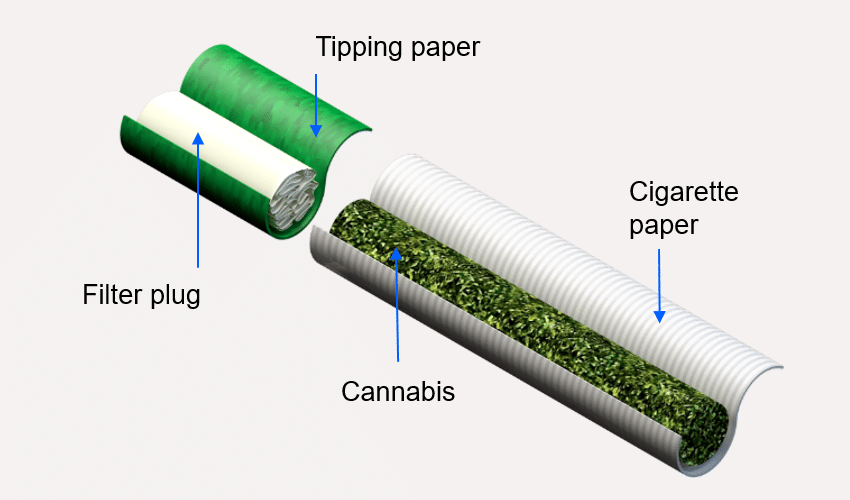

When opening a traditional cigarette field, customers instantly discover the filter connector. Along with potential discount of dangerous substances, filter plugs enhance pre-roll look and taste. With over 80% of filters all around the world produced on Körber’s filter marshmakers, Körber collaborates with clients to develop modern filters. These embrace the capsule filter with a crushable flavoring (eg mint) and the multi-filter that mix segments equivalent to coal and acetate. The shrunken paper filter plug that was as soon as standard in France has made a comeback as a result of demand for biodegradable supplies. The crutch tip, typically discovered in lots of pre-rolls, displays the rising reputation of paper filters. The filter connectors are connected to the hashish bar with a rocker paper. This rocker paper offers a superb alternative for product adjustment with completely different colours and logos.

© Körber Applied sciences

© Körber Applied sciences

Materials preparation and air movement management

Based mostly on the expertise of the tobacco business, hashish manufacturing advantages from methods equivalent to relaxation and cooling to arrange supplies for downstream processes. Nonetheless, mixing that was initially met with skepticism can standardize hashish properties, making certain a constant and cozy smoking expertise, particularly with psychoactive medication. With 75 years of experience in tobacco preparation equipment, Körber makes use of this data to refine the hashish preparation course of.

Airflow Management is a vital consider mastering the smoking expertise. Cigarette firms have perfected the best mixture of product hardness and air movement to make sure a sluggish, fulfilling combustion. The continual cigarette manufacturing precept, mixed with cautious filler preparation, permits hashish firms to acquire related measurements. Perforated rocking paper or on-line perforation improves airflow and can be utilized in case of a lighter style eager to be achieved.

About Körber

The Körber groupWith over 12,000 staff around the globe, machines and options throughout medicines, tissues and tobacco industries present. Körber Logistics gives automated warehouse and bundle dealing with options, whereas Körber Digital delivers AI-based options. Körber Applied sciences (previously Hauni Maschinenbau), with over 4,000 staff, leads in tobacco machines and options. For over three years, Körber has been providing pre-roll producers tailor-made to the hashish business. The compact TFM machine successfully fills pre-formed cylindrical tubes, which is considerably more cost effective than cones, at 80 cpm. Along with this, the Cantos and the Nano-H machines use the precept of steady cigarette making. Körber’s pre-roll producers deal with high-HC materials and industrial hemp with precision and Körber helps clients optimize the whole manufacturing course of, from materials preparation to manufacturing movement, and with the selection of supplies (rocker paper, and so on.).